You are here: Foswiki>Gunwiki Web>LegalCalifornia>LegalCaliforniaHK>ProcFixG3Mag (15 May 2012, SeanNewton)Edit Attach

Fixing a G3 / PTR-91 Magazine

By Rorschach, of Calguns The purpose is to lock a 10 round magazine in unlisted HK style weapons, thus complying with the requirements set forth in SB23. I made this lock to fit the JLD Enterprises PTR-91 rifle, which is a near exact homage to the Heckler and Koch HK-91 and G3 rifle. This may work for other non-listed HK's (SR-9, MSG-90) and other H-Klones as well (SW, Vector, Bobbies). Excuse my piss poor pics. I started by measuring the diameter of the mag release button (10mm), the diameter of the release underneath the button (8mm, a 5/16" drill bit will work), and the distance between the receiver and the button (little less than 1/8", about .120).

I found a nice scrap of 1/8" steel that would fit between the mag button and the reciever, with some filing.

I found a nice scrap of 1/8" steel that would fit between the mag button and the reciever, with some filing.

After drilling a 5/16" hole, and grinding off some excess material, (lots of trial and error) heres what I ended up with:

After drilling a 5/16" hole, and grinding off some excess material, (lots of trial and error) heres what I ended up with:

After more filing and grinding, a test fit:

After more filing and grinding, a test fit:

Heres a view from the rear of the magwell, lock is on the right. Please note the top of the lock has been tapered and rounded with a file to fit contour of the receiver. Pardon my thumb.

Heres a view from the rear of the magwell, lock is on the right. Please note the top of the lock has been tapered and rounded with a file to fit contour of the receiver. Pardon my thumb.

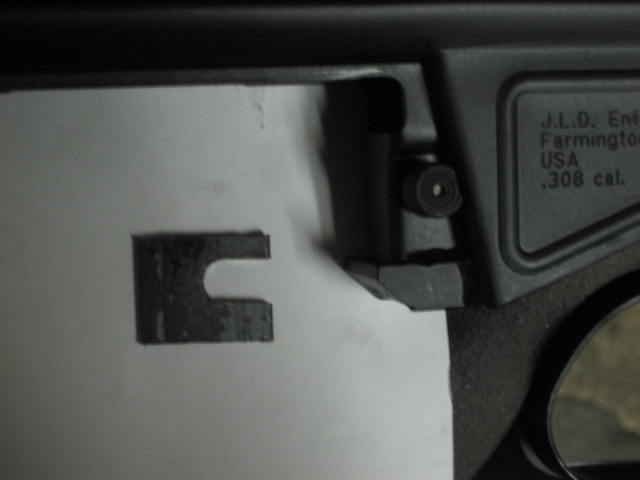

Heres a the completed maglock, after much filing to fit. In order for the trigger housing to close over the lock, I had to remove about .020 or .030 of material around the edges, leaving it .120 just around the slot. Lots of filing and test fitting here.

Heres a the completed maglock, after much filing to fit. In order for the trigger housing to close over the lock, I had to remove about .020 or .030 of material around the edges, leaving it .120 just around the slot. Lots of filing and test fitting here.

Here's the lock in position, note ten round magazine has been inserted.

Reassembling rifle with lock installed:

Here's the lock in position, note ten round magazine has been inserted.

Reassembling rifle with lock installed:  Locked in place and ready for trigger housing/pistol grip.

Locked in place and ready for trigger housing/pistol grip.

Trigger housing closed, holding lock securely in place.

Trigger housing closed, holding lock securely in place.

Completed rifle with locked 10 round magazine in place, pistol grip and flash supressor. HK collapsible stock on the way from http://www.RobertRTG.com and HK wide forearm coming from http://www.top-notchparts.com

Completed rifle with locked 10 round magazine in place, pistol grip and flash supressor. HK collapsible stock on the way from http://www.RobertRTG.com and HK wide forearm coming from http://www.top-notchparts.com

I used a pair of vernier calipers, hacksaw, drill press with 5/16" bit, bench grinder, bench vise, a large file, and a pair of vise grips (to hold while grinding). I used a 2" scrap of 1/8" steel that I found under my dad's bandsaw. It took me about 2 hours to do, most of which was fitting, filing and re-fitting. No doubt someone with a Bridgeport mill, or even a Dremel could do this faster. Hell, even a 5/16" washer of the right thickness cut in half and ground to shape will prolly work. You can choose to finish it with matte black spraypaint, or leave it natural steel. Duracoat makes an HK finish that may look pretty good on this.

Although the magazine can be removed without tools, one must disassemble the rifle in order to do so. Once the pistol grip is removed, the lock, and magazine are easily removed. At this point, the magazine is detatchable, but there is no evil pistol grip or, if you are so inclined, collapsible stock, as they have just been removed. Be aware, that although one can swap magazines in this fashion, there must be no other evil features on the rifle, such as flash hider, foward pistol grip, etc. and you must replace the lock before reassembling the rifle, or you will be in violation.

Much thanks to Pat at Metroshot, and my dad who let me use his truck repair shop.

I would appreciate any comments and suggestions, either legal or technical.

I used a pair of vernier calipers, hacksaw, drill press with 5/16" bit, bench grinder, bench vise, a large file, and a pair of vise grips (to hold while grinding). I used a 2" scrap of 1/8" steel that I found under my dad's bandsaw. It took me about 2 hours to do, most of which was fitting, filing and re-fitting. No doubt someone with a Bridgeport mill, or even a Dremel could do this faster. Hell, even a 5/16" washer of the right thickness cut in half and ground to shape will prolly work. You can choose to finish it with matte black spraypaint, or leave it natural steel. Duracoat makes an HK finish that may look pretty good on this.

Although the magazine can be removed without tools, one must disassemble the rifle in order to do so. Once the pistol grip is removed, the lock, and magazine are easily removed. At this point, the magazine is detatchable, but there is no evil pistol grip or, if you are so inclined, collapsible stock, as they have just been removed. Be aware, that although one can swap magazines in this fashion, there must be no other evil features on the rifle, such as flash hider, foward pistol grip, etc. and you must replace the lock before reassembling the rifle, or you will be in violation.

Much thanks to Pat at Metroshot, and my dad who let me use his truck repair shop.

I would appreciate any comments and suggestions, either legal or technical. | I | Attachment | Action | Size | Date | Who | Comment |

|---|---|---|---|---|---|---|

| |

HKmaglock002.jpg | manage | 39 K | 25 Aug 2006 - 09:06 | SeanNewton | Measuring the mag release button |

| |

HKmaglock007.jpg | manage | 53 K | 25 Aug 2006 - 09:07 | SeanNewton | Measuring height of the button |

| |

HKmaglock025.jpg | manage | 27 K | 25 Aug 2006 - 09:08 | SeanNewton | Fitting the scrap metal |

| |

HKmaglock030.jpg | manage | 27 K | 25 Aug 2006 - 09:10 | SeanNewton | Roughly in the right shape |

| |

HKmaglock034.jpg | manage | 56 K | 25 Aug 2006 - 09:11 | SeanNewton | Test fitting the mag lock |

| |

HKmaglock036.jpg | manage | 29 K | 25 Aug 2006 - 09:13 | SeanNewton | Mag lock in place |

| |

HKmaglock040.jpg | manage | 60 K | 25 Aug 2006 - 09:14 | SeanNewton | After trimming to fit the rear |

| |

HKmaglock042.jpg | manage | 60 K | 25 Aug 2006 - 09:25 | SeanNewton | Close-up on installed maglock |

| |

HKmaglock043.jpg | manage | 59 K | 25 Aug 2006 - 09:24 | SeanNewton | Closing it up, lock in place |

| |

HKmaglock044.jpg | manage | 59 K | 25 Aug 2006 - 09:16 | SeanNewton | Reassembling rifle with lock installed |

| |

HKmaglock052.jpg | manage | 73 K | 25 Aug 2006 - 09:25 | SeanNewton | Completed rifle, lock installed |

Edit | Attach | Print version | History: r3 < r2 < r1 | Backlinks | View wiki text | Edit wiki text | More topic actions

Topic revision: r3 - 15 May 2012, SeanNewton

%META:TOPICINFO{author="ProjectContributor" date="1231502400" format="1.1" version="1"}%

Copyright © by the contributing authors. All material on this collaboration platform is the property of the contributing authors.

Copyright © by the contributing authors. All material on this collaboration platform is the property of the contributing authors. Ideas, requests, problems regarding Foswiki? Send feedback